Bring Visual Context to Your Assets

trusted by fast-growing startups and global enterprises

SHARE, Connect, Scale

Turn 3D Scan Data into Actionable Operational Insight

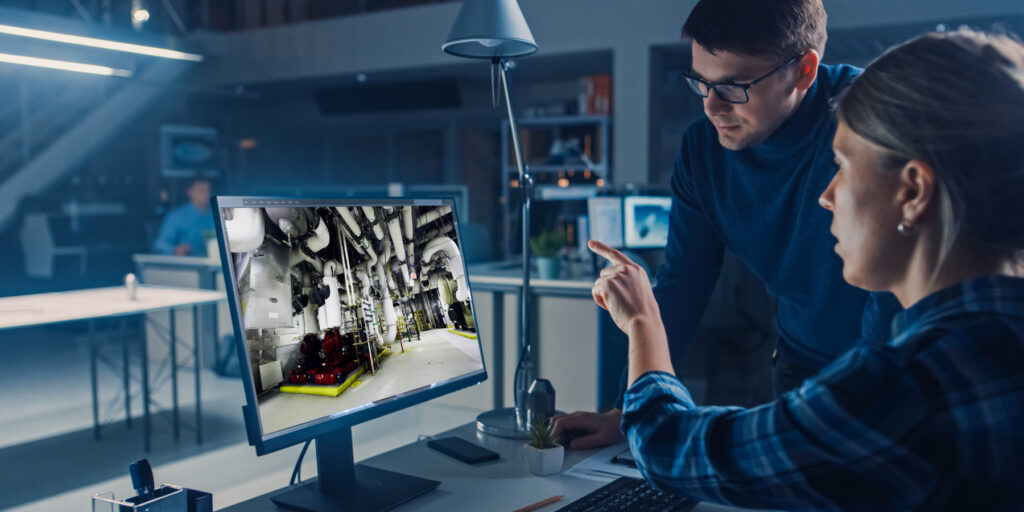

RealityTwin™ is a real-time, cloud-native platform that transforms 3D scan data into a visual environment. It empowers teams with a shared facility view, using spatial context and connected data to plan, execute, and optimize work effectively.

Up to 90%

Reduced time spent in the field

Scalable

Ready to integrate with Enterprise modeling

Up to 30%

Reductions for on-site inspection hours

Key Differentiators

Visual

Integrated

Scalable

Navigation

Manage a visual layer of your existing conditions

- Combine all your 3D scanning data into a single visual environment

- Easily update any area of your facility by layering new 3D scans

- Clean up noise or artifacts in your 3D scanning data

Transform static 3D scans into an interactive visual twin

-

Turn static 3D scans into a structured, interactive digital twin

-

Quickly isolate assets and make them selectable

-

Define information-rich asset metadata templates

-

Use the integrated search engine to quickly find what you need

Connect all your enterprise systems of record

- Enrich your visual assets by connecting various data systems

- Link your systems of record — ERP, MES, CMMS, IIoT, and more

- Manage secure data access with user-based permissions

Navigate complex sites with ease in 3D

- Interactively traverse spatial datasets within a high-fidelity 3D environment

- Perform asset-level verification and location analysis in context

- Remotely assess operational readiness and site conditions for planning and execution

IN-PLATFORM FEATURES

Tailored for Your Use Cases, Built for Real-World Impact

RealityTwin™ empowers your teams across the asset lifecycle, especially in operations and maintenance, by bringing clarity, speed, and collaboration to your most critical workflows.

Virtual Tours & Remote Monitoring

Replace costly travel with up-to-date visual context. Give all your employees secure, remote access to current site conditions.

Site Condition Monitoring

Use updated 3D scans to track facility changes and ensure all stakeholders are working from the same visual reference.

Operational Training & Safety Reviews

Use as-built environments to create immersive SOPs, document hazards, and reinforce safety, while reducing physical walkthrough risks.

Asset Lifecycle Management

Track changes, sync metadata, and connect systems like CMMS and ERP for reliable, visual asset tracking.

Frequently Asked Questions

Is RealityTwin™ compatible with my existing scans?

Yes. RealityTwin™ supports LiDAR, SLAM, drone, and photogrammetry scans. You can align data using georeferencing (recommended) or with built-in manual alignment tools. Multi-source scans can be layered into a unified, navigable environment.

Can we connect RealityTwin™ to our ERP or asset systems?

Absolutely. With RealityConnect™, you can sync RealityTwin™ with SAP, IBM Maximo, AVEVA PI, AWS SiteWise, and other systems—enabling real-time data access and bidirectional metadata syncing at the asset level.

How does pricing and licensing work?

RealityTwin™ uses a flexible pricing model:

- Storage-based: Pay for the volume of hosted and processed data (GB or TB)

- User-based: Floating licenses allow multiple users to share access, only paying for the number of concurrent users

- Role-based access: Free viewing for general users; licenses only apply to those authoring, editing, or managing data

It’s designed for phased rollouts across divisions or sites—ideal for scaling without upfront lock-in.

Is RealityTwin™ usable by non-technical teams?

Yes. RealityTwin™ includes a hybrid interface with both 3D mesh and photo-based views, allowing field techs, maintenance leads, and even executive stakeholders to explore and interact with the environment without needing CAD or scanning expertise.

Can our contractors or scanning partners upload data directly to RealityTwin™?

Yes. RealityTwin™ supports role-based access for external partners. You can assign upload permissions, require data formatting standards (e.g., meshable, georeferenced), and track deliverables per site or project. This ensures your data is usable from day one—without extra cleanup or back-and-forth.