The Challenges

Shutdowns are complex and high-cost events

2D plans and site visits miss critical details

Risk of crane conflicts, equipment delays, and space mismanagement

Every day of downtime costs millions

The Benefits with Prevu3D

Simulate crane lifts, routes, and laydown areas in 3D

Validate feasibility and identify conflicts before execution

Optimize equipment, space, and resources with confidence

Enable collaboration across engineering, operations, and contractors

Reducing risk and downtime in high-stakes industrial outages

Shutdowns and turnarounds are some of the most complex and expensive events in an industrial facility’s lifecycle. These planned outages require replacing, maintaining, and upgrading equipment under tight schedules. Success is dependent upon the precise coordination of work crews, heavy equipment usage, and the efficient use of laydown yards. Precision planning is key for these outages where schedules are developed and measured down to the minute.

Traditionally, shutdown planning relies on 2D drawings, manual site visits, and assumptions about available space. This makes it difficult to confirm whether large equipment can be safely moved, where cranes should be positioned, or how temporary laydown areas will affect ongoing operations. The result is increased risk, costly delays, and higher overall project costs.

Maintenance and operations engineers needed a better way to visualize and validate turnaround plans before execution.

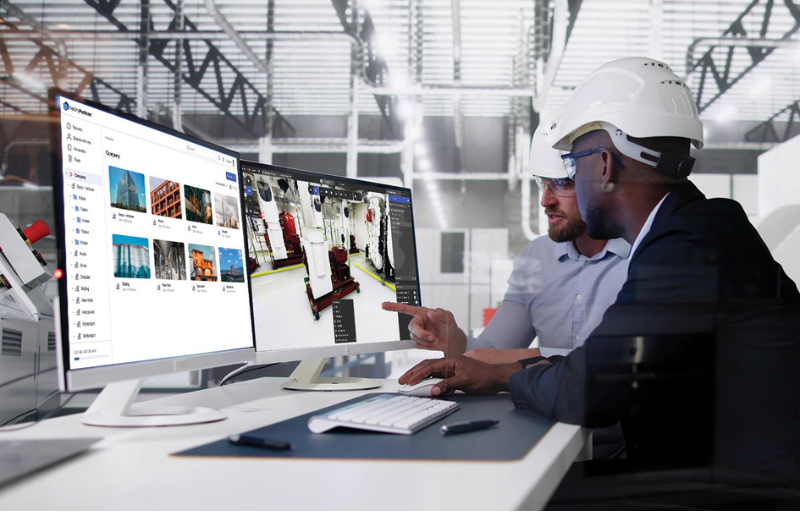

The Prevu3D Approach

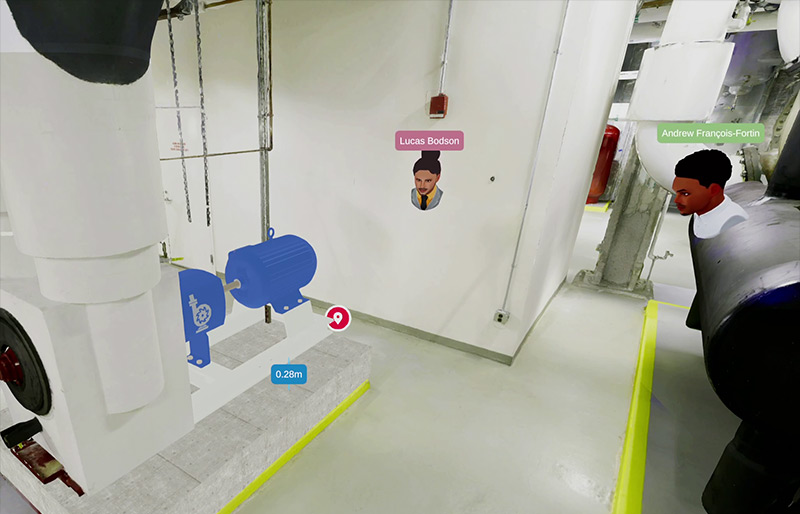

Prevu3D provided a way to simulate shutdown and turnaround activities in a virtual environment. By scanning the facility and importing the 3D mesh into RealityPlan™, engineers could:

- Test crane placement and reach for heavy lifts.

- Simulate equipment removals and replacements in confined spaces.

- Plan laydown areas for temporary storage during the turnaround.

- Validate transport routes within the facility to avoid conflicts.

This approach allowed planners to assess feasibility and sequence activities with a level of clarity that traditional drawings could not provide.

The Results

Using Prevu3D transformed the shutdown planning process:

- Better planning. Equipment swaps and crane lifts were simulated in advance, reducing uncertainty.

- Reduced risk. Potential conflicts were identified and remediated early, avoiding costly surprises during the actual shutdown.

- Optimized resources. Crane and laydown area utilization were planned with precision, ensuring efficient use of space and equipment.

- Improved collaboration. Engineers, contractors, and operations teams could review turnaround plans together in a shared 3D environment.

By visualizing the shutdown before execution, the team reduced delays and improved confidence in delivering the turnaround on time and on budget.

Why It Matters

Turnarounds are high-stakes events where every day of downtime can cost millions in lost production. Mistakes or miscalculations in planning can quickly escalate into schedule overruns and financial losses.

Prevu3D enables maintenance and operations engineers to bring realism and accuracy into turnaround planning. By validating equipment swaps, crane lifts, and logistics early and virtually, teams reduce risk, improve safety, and minimize the duration of every shutdown window.

In an industry where time is money, Prevu3D ensures shutdowns and turnarounds are executed right the first time.

Avoid costly delays in your next shutdown. Book a demo with our experts and see how Prevu3D helps reduce risk, optimize resources, and keep turnarounds on schedule.