October 27, 2023 – Elle Magni

Maximizing data and engineering concept design with Prevu3D software

The global business landscape is changing rapidly, with technology, environmental, and sustainability trends reshaping the way industrial organizations operate. These organizations require innovative solutions to adapt to this shift.

In the post-pandemic era, the urgency to adapt has intensified. As a result, organizations are actively seeking efficient ways to streamline their operations and meet their digital transformation needs.

Engineering challenges

In complex asset-heavy industries, engineers face challenges in managing design project time, cost, and reporting across the organization. Valuable engineering data is often scattered across various sources such as spreadsheets, drawings, 3D models, laser scans, and printed documents, making it difficult to maximize or reuse the data effectively.

From the concept design phase to project delivery lack or outdated site documentation results in significant time lost searching for, traveling to gain and validating information. Engineering leads strive to establish a single source of truth to facilitate collaboration throughout project lifecycles.

Turn data into a rich visual context

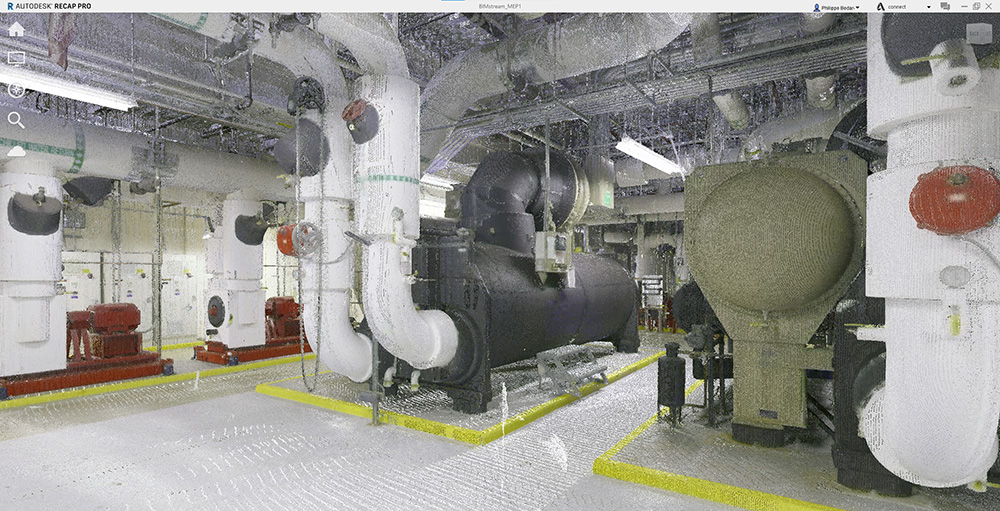

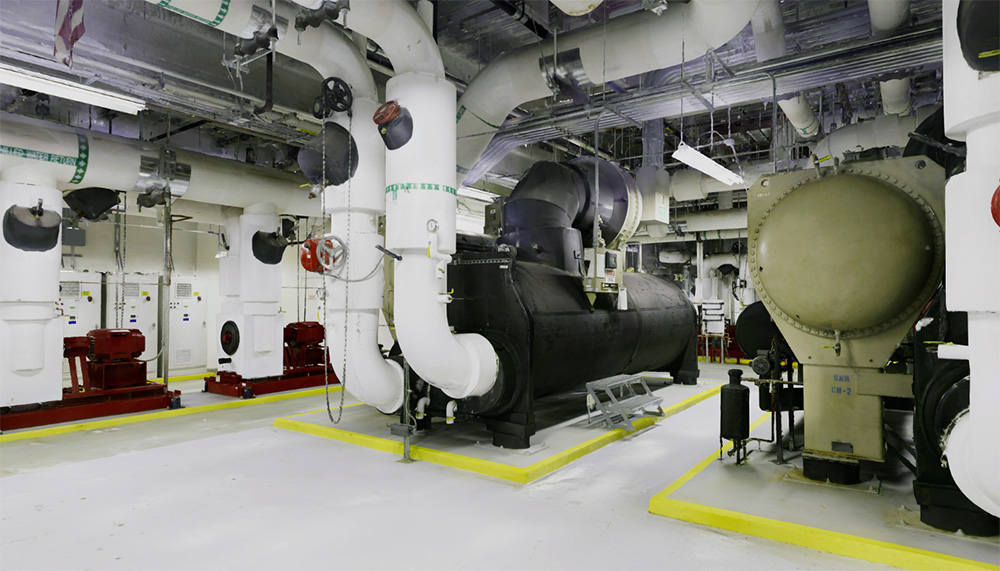

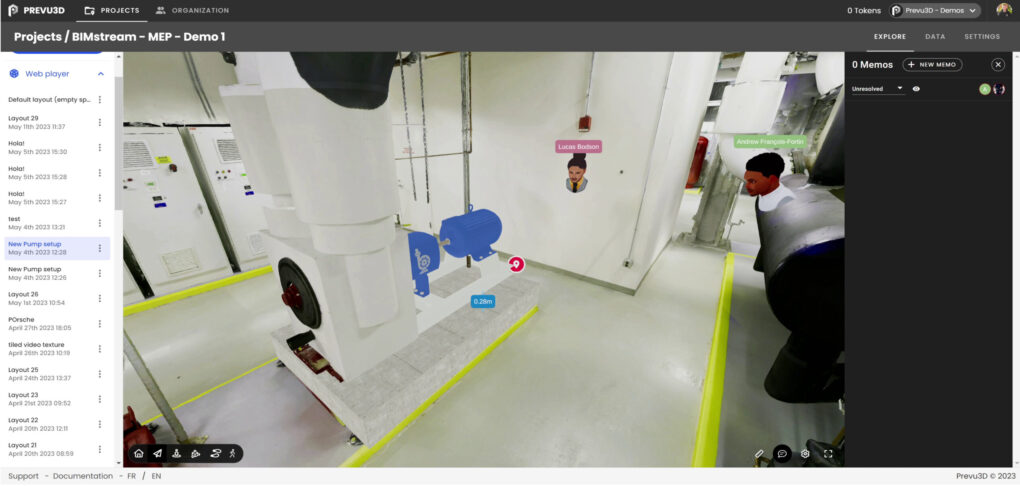

Reality capture has become an essential aspect of design engineering projects, as it allows for the rapid capture of existing facility conditions. However, working with point clouds, which are dense sets of 3D data points, can be challenging due to their heaviness and difficulty to visualize up close. Using Prevu3D software, data can be quickly transformed into accessible 3D mesh models. In fact, we typically reduce the file size by 95% for terrestrial scans without compromising the quality or the use of specialized hardware.

Point cloud rendering (above)

Prevu3D meshes (above)

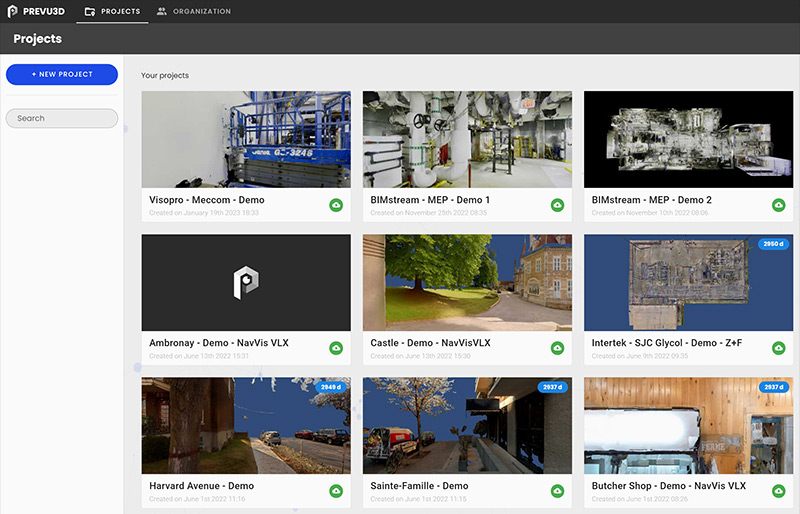

Through this innovative approach, we can deliver highly precise and intuitive digital replicas of spaces and assets. Users can work and collaborate remotely in our web and desktop applications, saving time and cost from site visits.

Prevu3D addressing key pain points in factory layout pre-design to uncover new opportunities, reduce risk and save costs:

- Improving pre-design & optimizing facility reconfiguration

- Centralizing documentation to reduce travel costs and delays

- Enabling input and recommendations for better decision-making

Instead of spending days, or even months, on your engineering concept design phase, with teams scrambling to gather missing measurements, facing growing costs and extended timelines, Prevu3D allows all users to instantly access, edit and share design iterations and documentation in the platform.

Empowering project stakeholders

When project stakeholders have the ability to navigate 3D environments, they can provide valuable feedback and actively participate in decision-making for better project outcomes.

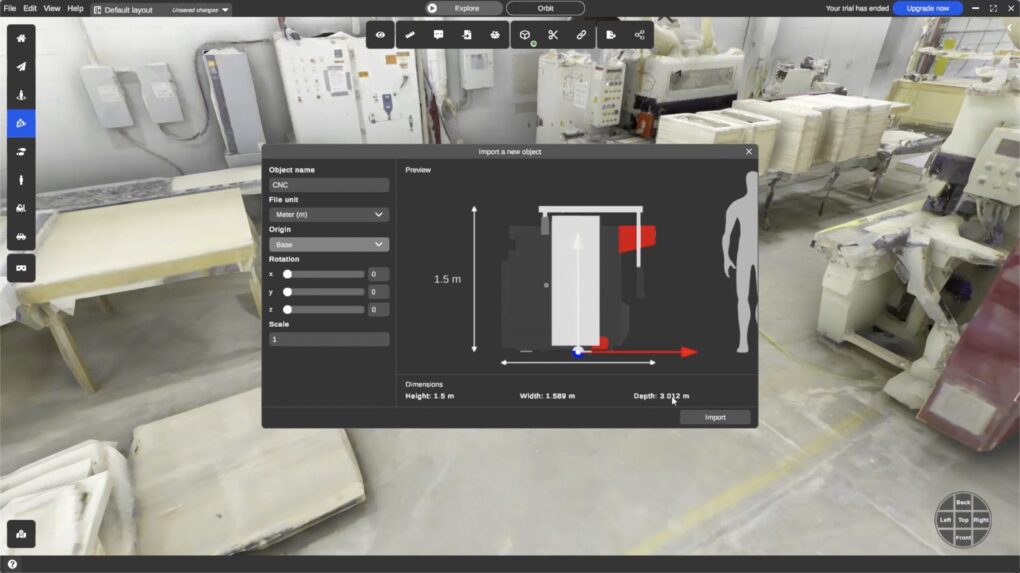

Using the Prevu3D platform, stakeholders can take measurements, rapidly create design iterations, and zoom into every detail to identify potential issues for less planning errors and faster project turnarounds.

Prevu3D workflow benefits

- Access accurate and up-to-date 3D documentation of your site

- Provide ultra-realistic replicas of environments for better visualization and understanding of sites, spaces and structures

- Edit your space and create new design iterations

- Enhance internal and external team collaboration

- Implement complex changes with precision

Prevu3D provides an end-to-end platform that enables industries to harness the potential of 3D, enabling efficient workflows, enhanced decision-making, and optimized resource allocation.

Take a step towards a more efficient and collaborative future with Prevu3D.