Why Digital Twin Initiatives Stall on the Factory Floor

Digital transformation leaders in automotive manufacturing aren’t asking for a “digital twin.” They’re being asked to reduce approval delays, cut unnecessary travel, and avoid costly rebuilds on the plant floor.

What gets labeled a digital twin is often introduced as a visualization initiative. But visualization alone rarely changes how decisions are made. It doesn’t shorten approval cycles. It doesn’t reduce rework. And it doesn’t scale beyond a small group of specialists.

The real opportunity isn’t in creating another model of the factory. It’s in changing how the organization understands, validates, and acts on the as-built world.

Many digital initiatives fail not because the technology is weak, but because they stop at viewing reality. The result is a point-cloud or model viewer that lives in isolation, adopted by a few experts, disconnected from engineering, operations, and the systems that drive action. That’s not transformation, it’s digitization without leverage.

For digital transformation leaders, this is where most initiatives stall. Visualization may prove that reality can be captured, but it rarely changes how approvals happen, how teams validate decisions, or how work actually gets executed. Faster approvals, fewer site visits, and less rework don’t come from better visuals; they come from changing how decisions move through the organization.

The real workflow problem digital twins are expected to solve

Digital twins are often introduced to improve how decisions are made. In practice, those decisions break down not because organizations lack data, but because physical and spatial reality is fragmented across engineering, operations, and planning workflows.

The result is a set of recurring bottlenecks that slow production engineering and plant-level decision-making:

- Approval loops dependent on physical presence

Layout changes, workstation reorganizations, and line adjustments often require repeated site visits to align engineering, operations, safety, and leadership around what will actually work in the physical environment. - Validation disconnected from real-scale context

Reviews rely on 2D drawings or partial 3D representations, forcing teams to mentally translate scale, clearances, and sequencing, increasing the likelihood that issues are missed until execution. - Rework discovered too late

Conflicts related to layouts, equipment access, safety zones, or material flow surface during implementation; when corrections are most expensive and disruptive to production.

These are not problems because manufacturing is complex; they exist because spatial reality is poorly delivered to decision-makers at the moment decisions are made.

McKinsey has repeatedly highlighted that digital twins create value only when they accelerate decisions across design, build, and operate loops — not when they exist as static representations of assets.

Where digital twin initiatives break down inside transformation programs

Many digital twin initiatives inside transformation programs focus first on visualizing data. That’s understandable; visualization is tangible and impressive. But visualization alone doesn’t fix approval latency, travel dependency, or rework.

In practice, transformation programs stall when:

- Only specialists can navigate or interpret the twin

- Spatial context isn’t trusted as an as-built reference

- The twin exists separately from operational and enterprise data

- Reviews still rely on screenshots, exports, or meetings outside the environment

Industry coverage reflects this reality. As Wired notes, industrial digital twins only deliver sustained value when they shift organizations from reactive problem-solving to anticipatory, shared decision-making—not when they remain isolated technical artifacts.

A different approach: replacing the decision loop, not the toolset

In a recent automotive manufacturing program we supported, the objective was not to “deploy a digital twin,” but to address a familiar production challenge: decision cycles around layout and line changes that were slow, travel-heavy, and prone to late rework.

Instead of starting with the full plant, the team focused on zones where layout changes were frequent and costly. The goal was simple: reduce the time and friction required to validate and approve changes.

From site-dependent approvals to reality-first decision-making.

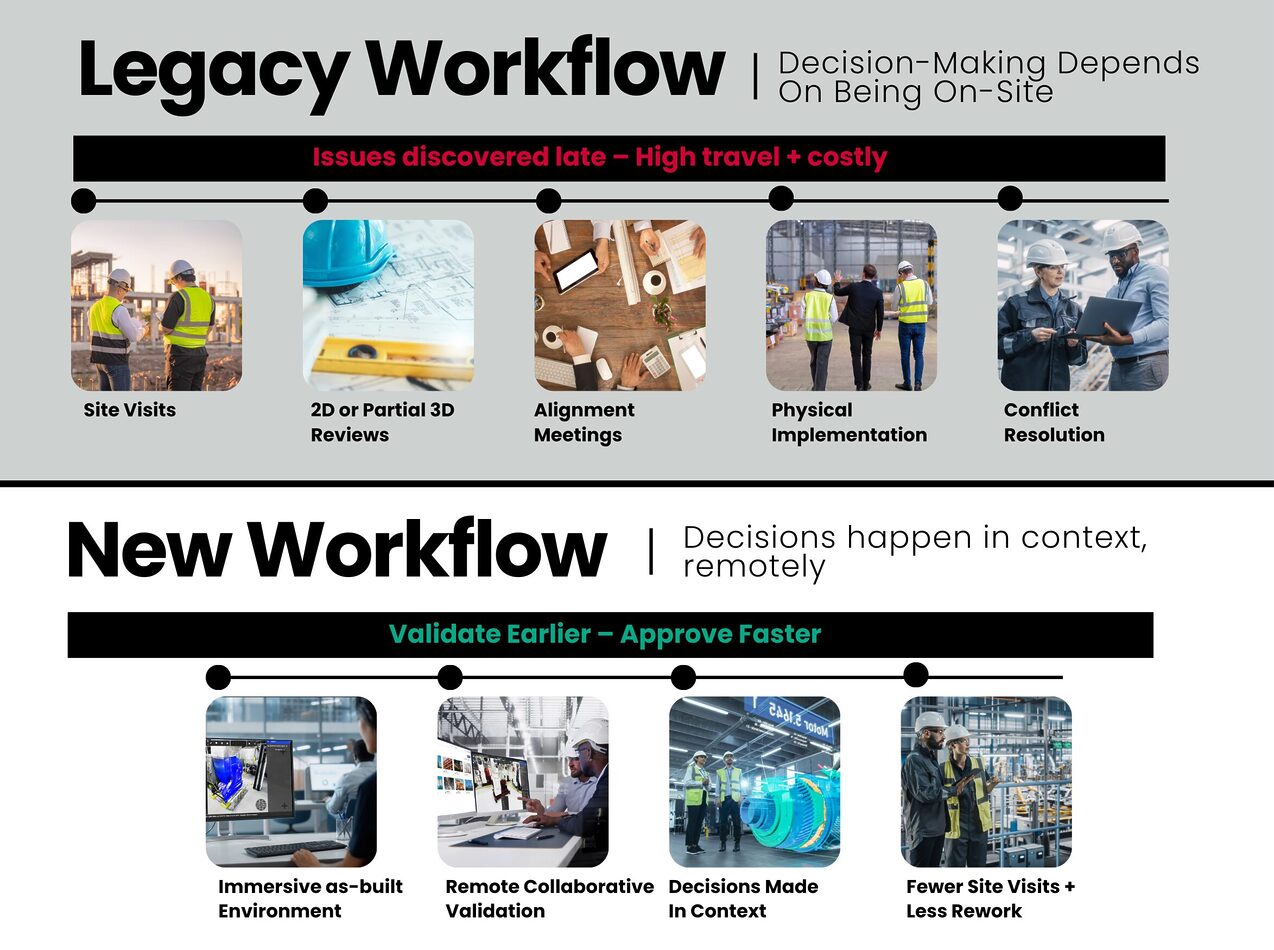

The legacy workflow depends on physical presence and late conflict resolution. The new workflow enables earlier validation, remote alignment, and fewer site visits.

This wasn’t about replacing engineering tools. It was about giving decision-makers a shared, trusted spatial reference.

Where Prevu3D fits—enabling decisions, not just visibility

Prevu3D’s role in this type of program is not as a reporting layer or a visualization add-on. It functions as a reality-based collaboration environment that sits between capture, planning, and operations.

This perspective reflects patterns we see repeatedly across automotive and industrial manufacturing programs, where reality data is introduced to shorten decision cycles rather than replace existing systems.

In this context, Prevu3D was used to:

- Convert raw reality capture data (from multiple capture methods) into a performant, navigable 3D environment teams could trust as an as-built reference

- Enable real-scale validation of layouts, clearances, and access before physical changes

- Allow non-specialist stakeholders—production engineering, safety, operations—to participate directly in reviews without training on complex CAD tools

This matters because adoption doesn’t come from technical completeness. It comes from usability under real operational pressure.

Making integration concrete (without creating another silo)

A core hesitation among digital innovation leaders is this: “If we adopt a digital twin, will it become another silo?”

Avoiding that outcome requires treating the twin as a connected reality layer, not an isolated viewer or a new system of record.

In this program, the spatial environment acted as a context layer:

- Physical assets in the 3D environment carried identifiers aligned with enterprise records

- Selecting an asset visually exposed operational attributes tied to those records

- That same identifier allowed downstream workflows, including field and AR-based use cases, to reference the same asset without duplicating data

The result was not one more database, but a shared spatial interface connected to existing enterprise systems.

That’s what allows planners, safety teams, and maintenance groups to operate from the same version of truth, even when their tools and workflows differ.

This approach aligns with broader manufacturing transformation research. Deloitte notes that digital twins create measurable impact when they are embedded into operational workflows and connected to enterprise systems, rather than deployed as standalone visualization tools supporting isolated teams.

Industry analysts increasingly emphasize that digital twins deliver value when they connect simulation, operations, and execution through shared context rather than isolated toolchains.

What changed in practice

By introducing a reality-first decision workflow, teams observed:

- Faster layout and change approvals, driven by remote, real-scale validation

- Reduced dependency on travel for cross-functional alignment

- Earlier detection of spatial conflicts, lowering the risk of late rework

- Improved cross-site consistency, as teams worked from a shared environment rather than region-specific files

These outcomes weren’t framed as “digital twin success.” They were measured as improvements in cycle time, coordination, and disruption — the metrics executives actually track.

The takeaway for innovation leaders

If you’re responsible for digital transformation in manufacturing, the key question isn’t whether your organization wants the outcomes promised by digital twins.

It’s whether a digital twin can actually deliver on them.

Specifically:

- Can it support spatial decisions without requiring constant site visits?

- Can it align engineering, operations, and safety around the same trusted view of reality?

- Can it surface conflicts early enough to prevent late-stage rework?

When a digital twin replaces approval bottlenecks and rework loops in day-to-day workflows, it earns its place. Platforms like Prevu3D enable this shift by turning as-built reality into a shared, usable decision environment — without asking organizations to replace their existing systems.

When it can’t, the twin becomes another well-intentioned platform that demonstrates potential, but rarely changes how decisions are made.

The difference isn’t fidelity. It’s whether reality is delivered in a form people can actually use to decide.

See a reality-first decision workflow in practice

Explore how Prevu3D helps automotive teams validate changes earlier, align remotely, and reduce rework—without replacing their existing systems.