Blog - September 4, 2025

How EPC Companies and Design Teams Are Accelerating Layout Planning with Prevu3D

Challenges

Slow, CAD-dependent reviews

Limited stakeholder access

Weeks of rework cycles

Benefits with Prevu3D

Real-time layout updates

Easy, browser-based input

Faster project throughput

The Hidden Bottleneck in Brownfield Expansion Projects

Brownfield expansions are notorious for complexity. Adding new units to existing facilities requires design teams to juggle a variety of documents, including equipment lists, process flow diagrams, and material estimates—often under tight deadlines. Traditionally, CAD designers spend weeks building layouts in complex and expensive 3D modeling tools, and have to host online model reviews with 20+ stakeholders in lengthy calls to capture comments and revisions.

But forward-thinking EPCs and design teams have found a faster way.

The Challenge

In a typical workflow, CAD designers own the entire layout review process. They import equipment objects into 3D models, develop multiple layout alternatives, and collect feedback during large review meetings. Stakeholders must rely on the CAD designer to “drive” the session, since most lack licenses for heavy modeling software. The result? Slow review cycles, schedule bottlenecks, and limited stakeholder collaboration.

As one EPC engineering manager put it:

Our CAD designer was the only one who could make changes. Every round of comments meant another week of rework before we could see the next version.

The Prevu3D Approach

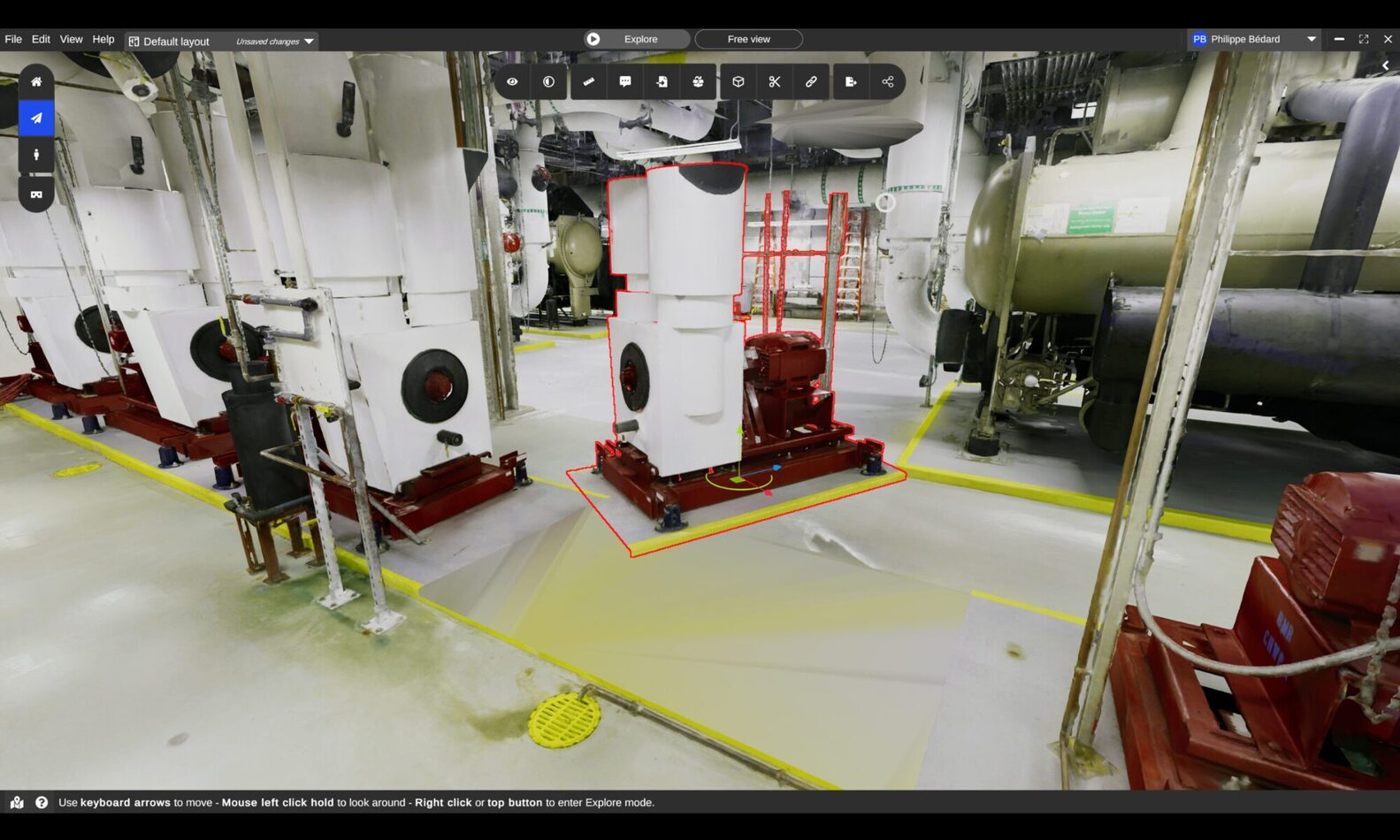

By combining drone or LiDAR scans of the existing facility with sized virtual objects, CAD designers can import everything into Prevu3D’s environment. Once published, layouts are instantly accessible in a browser—no specialized software or plugins required.

This means:

- Faster layout planning – Designers arrange equipment virtually and update layouts in near real time.

- Asynchronous collaboration – Engineers, constructability specialists, and suppliers can leave comments and annotations directly in the model.

- Reusable objects – Libraries of virtual equipment can be pulled into new projects, accelerating repeatable workflows.

- Built-in measurement & annotation – Stakeholders don’t just view layouts; they can measure, mark up, and give precise feedback in context.

- Secure sharing – Teams can collaborate across organizations, with stakeholders accessing the model via a simple, permission-controlled link.

What used to take a week of layout work and another two weeks of back-and-forth was reduced to hours using Prevu3D. In one case, the CAD designer republished an updated layout before the design review call had even ended.

– Jacob Gleason, former Senior Digital Strategy Advisor at Chevron

The Result

- Accelerated design cycles – Layouts can be revised and published in hours instead of days or weeks.

- Expanded stakeholder input – Feedback from engineers, contractors, and suppliers, without licensing or specialized software barriers.

- Greater project throughput – With fewer bottlenecks, design team managers are able to evaluate and process more opportunities without adding additional resources.

- Seamless external collaboration – Published models can be shared with third parties such as OEMs, service providers, and regulatory agencies. This enables broader input on designs without complex IT barriers.

Why It Matters

For EPC firms, early-phase design capacity is a competitive advantage. By streamlining brownfield expansion workflows, Prevu3D helps design teams evaluate more projects, engage more stakeholders, and reduce risk before committing capital.

Book a demo with Prevu3D and see how engineering leaders cut design cycles, eliminate costly site visits, and prevent million-dollar errors before they happen.