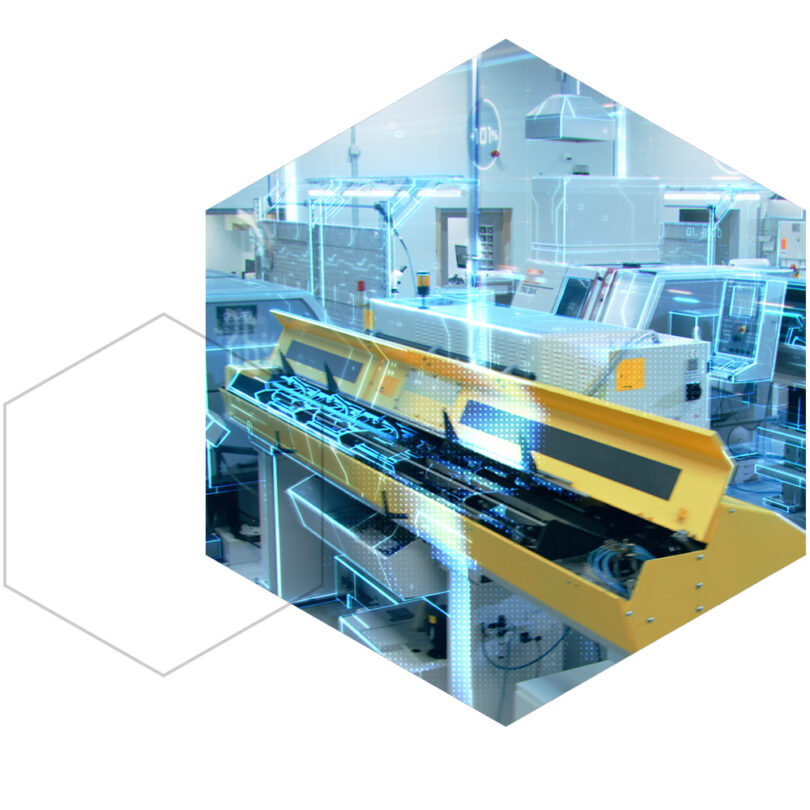

Digital Twin in Manufacturing

WHAT WE DO

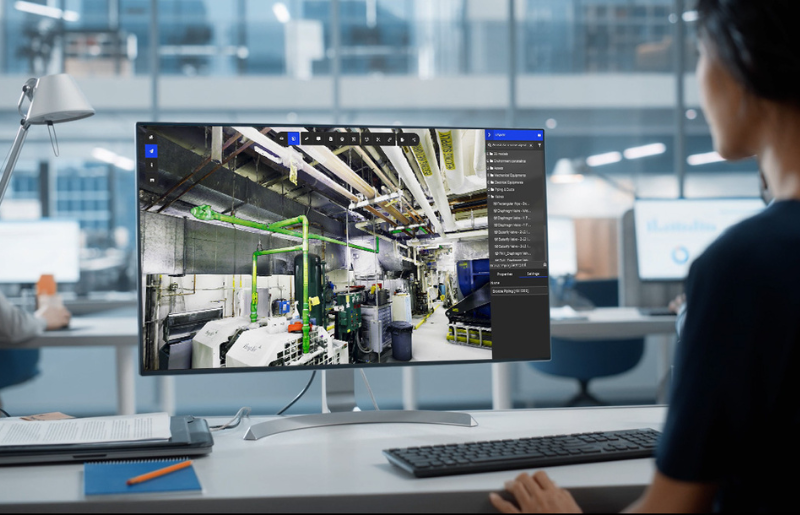

Leverage digital replicas to visualize and identify areas for improvement and streamline design engineering processes

Enhance reconfiguration to transform operations with Prevu3D digital twins

Prevu3D helps companies use digital twins for facility planning and upgrades. By rapidly creating iterations for viability assessment, it allows for a better decision-making process.

- Optimize factory layouts.

- Plan for faster changeovers to increase productivity.

- Lower costs for skills and safety training to create a better work environment.

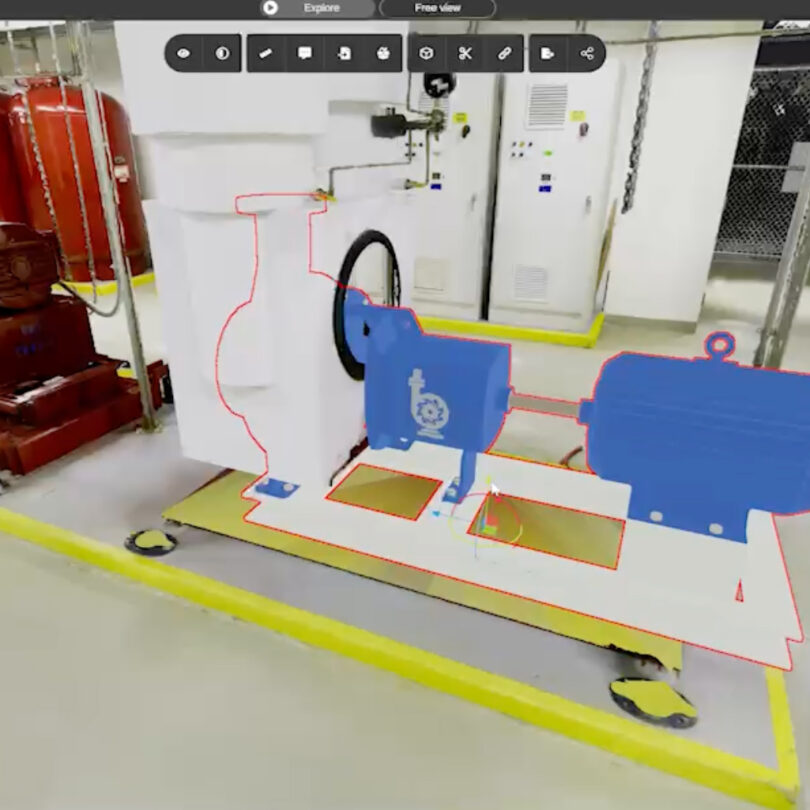

Prevu3D digital twin key features for the manufacturing industry

Centralize all your reality capture

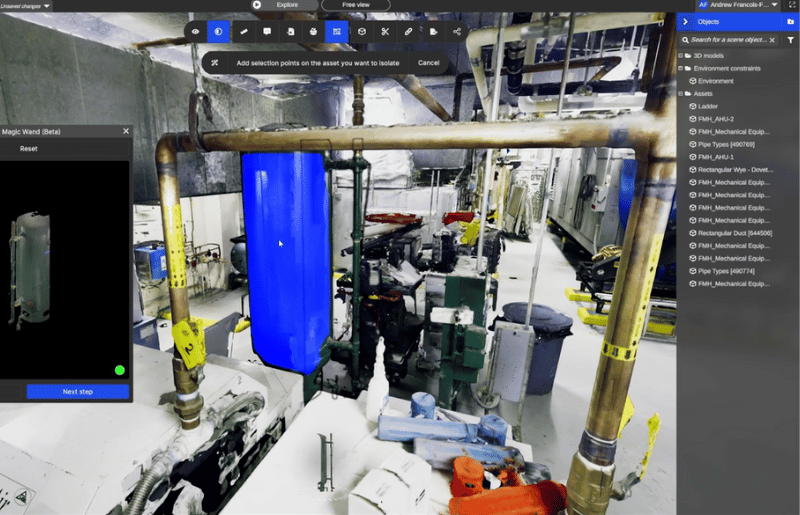

RealityAsset definition

Design engineering tools

What you need to know

What is a digital twin?

A digital twin is a virtual replica of a real-world space or physical asset. Digital twins reflect the current asset condition and can be continuously updated with data from its physical counterpart. Digital twins can create simulations and predict future behavior, streamline collaboration and optimize operations.

What is a point cloud?

A point cloud is the raw material of a digital twin. Point clouds are created by panning a 3D scanner back and forth over walls, piping, pieces of equipment, vehicles and much more. The scanner head emits a laser beam or optical-spectrum light and detects the reflection. The scanner measures the timing and intensity of the reflection. It creates millions of points each with a unique position and orientation in space. Multiple passes of a scanner create a dense cloud of points, hence the name. While raw point clouds are rich sources of information, they are too big to use in a digital twin. Prevu3D turns these raw point clouds into actionable data.

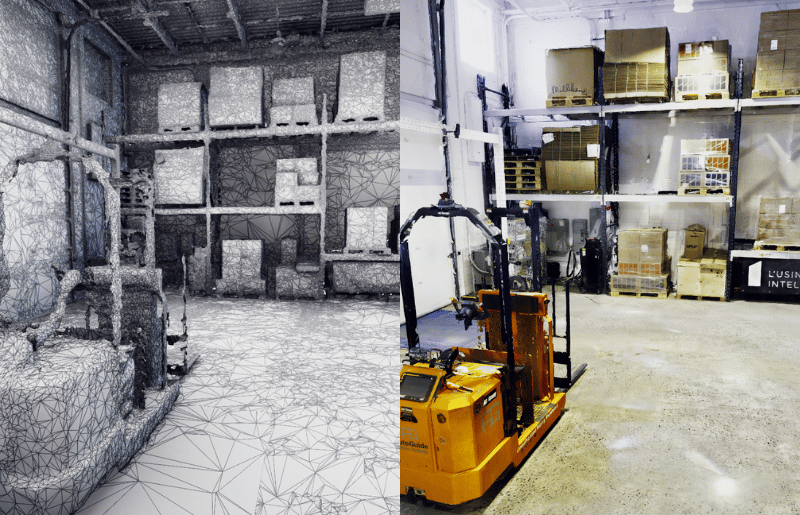

What is a polygon mesh?

Processing a point cloud with specialized computer software and hardware creates a polygon mesh. The software creates lines to connect each point to its adjacent points based on analysis of the position and orientation of each point. Adjacent points are joined by lines to form an array of tiny polygonal shapes. This array is a polygon mesh. The higher the density of the point cloud the more surface details appear on the mesh. A variety of data compression techniques can be applied to meshes to reduce the size of the mesh to content that users can interact with on wireless mobile devices, while preserving detail. Prevu3D has the best meshing solution on the market for digital twins.

General Mills: leveraging Prevu3D software to streamline engineering workflows