Case Study

Maritime Information Modelling: How Ataris and Prevu3D Delivered BIM at Sea with Norse Ship Management

Challenges

- Reliance on photos, drawings, and repeated site visits

- Slow ship–shore coordination and decision delays

- Pressure to improve efficiency, safety, and sustainability

Benefits using Prevu3D

- Remote familiarization and inspections with fewer site visits

- Faster, more accurate planning for maintenance and retrofits

- Shared 3D workspace that improves collaboration and audit readiness

Challenges

Reliance on photos, drawings, and repeated site visits

Slow ship–shore coordination and decision delays

Pressure to improve efficiency, safety, and sustainability

Benefits Using Prevu3D Solutions

Remote familiarization and inspections with fewer site visits

Shared 3D workspace that improves collaboration and audit readiness

Smooth cloud-based collaboration

The Mari-Twin deployment aboard MV Chattanooga marks a new era of digital ship management.

Project Context

Norse Ship Management partnered with Ataris to deploy Mari-Twin aboard the MV Chattanooga, creating a complete digital twin of the vessel using the Prevu3D platform.

More than a visualization tool, Mari-Twin, hosted on Prevu3D’s RealityPlatform™ , is an interactive, browser-based workspace that allows crews, superintendents, and technical teams to explore, measure, and plan with accuracy. The system brings together visual context, operational data, and spatial intelligence in one accessible environment.

Laser scanning inside the vessel engine room during data capture.

Laser scanning inside the vessel engine room during data capture.

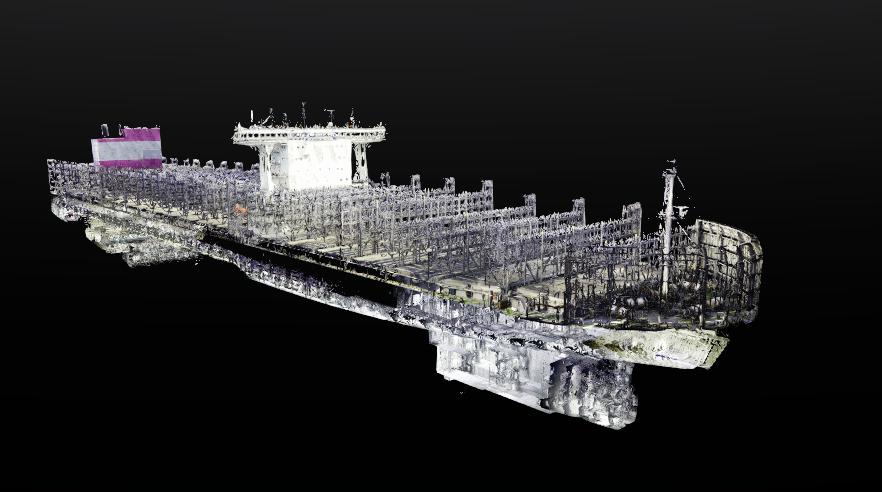

High-resolution 3D scan of the MV Chattanooga processed through Prevu3D to create a fully navigable vessel-scale Visual Twin.

High-resolution 3D scan of the MV Chattanooga processed through Prevu3D to create a fully navigable vessel-scale Visual Twin.

Key operational use cases include:

- Crew familiarization and onboarding – explore the vessel digitally before joining, improving safety awareness.

- Retrofit and maintenance planning – assess layouts and space constraints remotely, accelerating decision-making.

- Remote inspections and safety reviews – verify conditions without site visits, cutting time and travel.

- Training and simulation – use real vessel environments for procedures and emergency drills.

- Chartering and ESG reporting – visual reference for sustainability audits and client demonstrations.

Before Mari-Twin, these workflows relied on static drawings, photos, or multiple site visits. By combining Ataris’ maritime expertise with Prevu3D’s immersive 3D technology, Norse now operates with a living digital asset that connects its people and information.

Challenges

The merchant vessel fleet is often described as “factories of the sea.” On land, modern factories use Building Information Modeling (BIM) to manage assets and workflows. Recognizing the need to modernize, Norse Ship Management worked with Ataris and Prevu3D to explore how Maritime Information Modeling (MIM)—BIM at sea—could improve decision-making, collaboration, and safety across teams.

Ship operators today face increasing pressure to enhance efficiency, meet sustainability targets, and improve crew safety—all while managing geographically dispersed teams. By adopting MIM through the Mari-Twin platform, Norse has taken a practical step toward meeting these challenges, proving that BIM principles can be successfully applied at sea.

The Solution: Mari-Twin and Prevu3D in Action

To bring MIM to life, Ataris deployed Mari-Twin aboard the MV Chattanooga. Using high-resolution 3D scans captured by Ataris, data was processed through Prevu3D’s RealityPlatform™ and RealityConnect™ tools to produce a fully navigable, photorealistic model accessible on any internet-enabled device—no specialist software required.

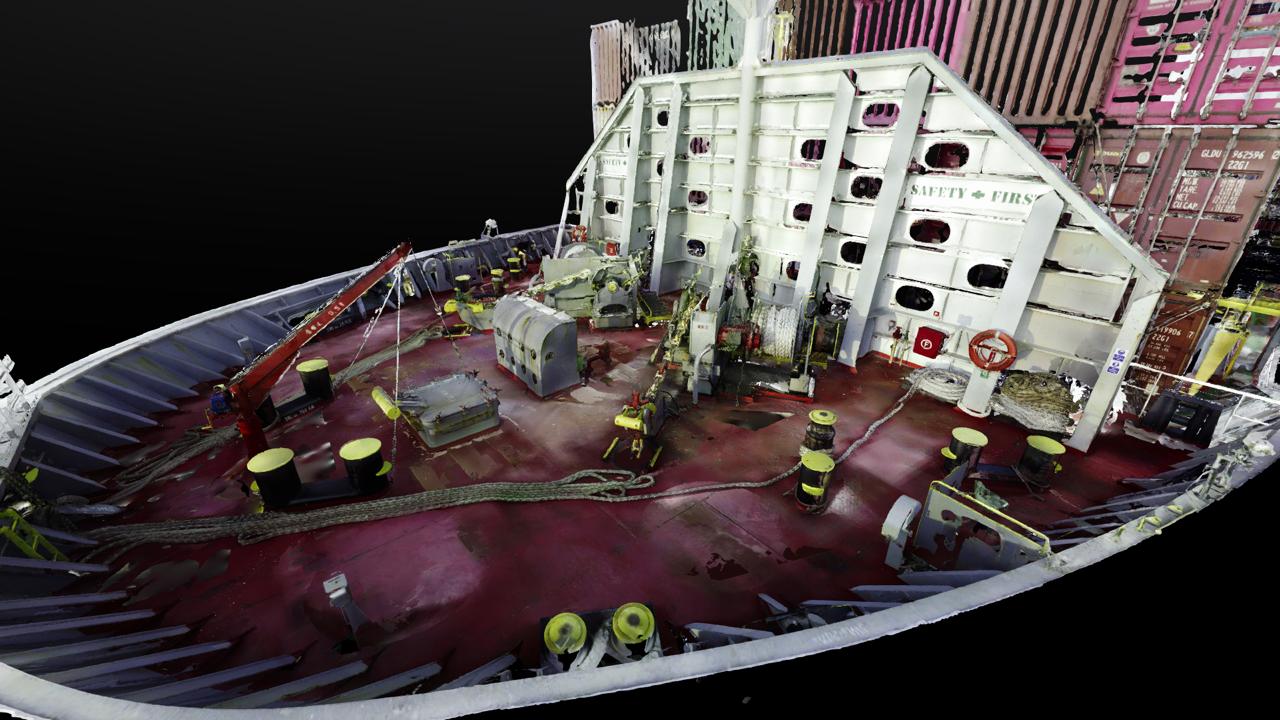

3D scan of the MV Chattanooga foredeck captured for the Mari-Twin Visual Twin.[/caption]

3D scan of the MV Chattanooga foredeck captured for the Mari-Twin Visual Twin.[/caption]

Mari-Twin integrates directly into daily ship management workflows, creating a bridge between on-board operations and shore-based decision-making.

Key outcomes:

- Operational accessibility: Navigate, measure, and annotate directly in-browser.

- Seamless integration: Works alongside existing planning and maintenance systems.

- Collaboration and training: Shared environment improves communication and safety awareness.

- Future-ready architecture: Compatible with Prevu3D plugins (RealityConnect™ for Revit, etc.) and maritime systems such as maintenance and HSQE.

Port-side walkway of the MV Chattanooga, supporting crew familiarization and safety awareness.

Port-side walkway of the MV Chattanooga, supporting crew familiarization and safety awareness.

This approach enabled Norse to move beyond static drawings and site visits—creating a shared digital workspace where every department operates from the same visual and spatial context.

Strategic Roadmap & Future Potential

At Norse Ship Management, we believe the future of ship management lies in connecting people, data, and decision-making—transforming every vessel into an intelligent, living digital twin ecosystem. Ataris is helping us bring this vision to life through the Mari-Twin platform, enabling practical digitalization across our fleet.

—Akshay Yadava, Managing Director, Norse Ship Management

For Norse Ship Management, Mari-Twin represents more than a single deployment—it’s the foundation for a connected digital ecosystem across the fleet.

Ataris and Prevu3D are now supporting next-phase integrations that link Mari-Twin to live operational data and third-party systems, including:

- Maintenance and asset management – aligning 3D context with service and inspection records.

- HSQE and compliance tools – embedding documentation and inspection evidence in the digital twin.

- ESG and carbon reporting frameworks – visualizing sustainability metrics alongside operations.

- IoT and sensor data – enabling predictive maintenance and condition monitoring.

- API-driven connections – integrating routing, weather, and training systems for real-time insight.

This roadmap positions Norse to evolve from a standalone digital twin into a fleet-wide, data-connected ecosystem—where every vessel operates as part of a unified, intelligent network.

Results and Impact

The Mari-Twin deployment aboard MV Chattanooga has delivered clear, practical value for Norse Ship Management.

Key results include:

- Enhanced operational readiness: Crews familiarize remotely, improving safety and reducing handover time.

- Improved retrofit and maintenance planning: Engineering teams plan work virtually, reducing time onboard and rework.

- Faster decision-making: Managers assess conditions through the model before mobilizing personnel.

- Reduced cost and carbon impact: Fewer site visits lower both travel and emissions.

- Audit and compliance confidence: Immersive visualization strengthens documentation for external reviews.

Supported by Prevu3D’s platform, Mari-Twin provides a dynamic, scalable environment that connects people, data, and spatial context in one place. Following this success, Norse is assessing wider applications across its fleet to further embed Maritime Information Modeling (MIM) principles into daily operations.

Industry Recognition

Technology deployment in shipping often stalls at the pilot stage, but Norse Ship Management broke that mold. Their pioneering mindset allowed us to deliver a solution that genuinely adds value—not just as a visual reference, but as a day-to-day operational tool.

— Samuel Lee, Managing Director, Ataris

Norse’s proactive approach has already drawn positive attention from auditors and industry peers, reinforcing its reputation as an early mover in maritime digitalization.

Next Steps

Interested in how digital twin technology can transform your operations?