General Mills Digital Twin Case Study

General Mills: leveraging Prevu3D software to streamline engineering workflows

Whether improving engineering practices or optimizing and modernizing plants, General Mills is driving efficiency by maximizing the use of reality capture data using Prevu3D Digital twin software solution

Get free access to this case study

About General Mills

General Mills, Inc. is an American multinational manufacturer and marketer of branded processed consumer foods. With over 20 plant locations, the company boasts a portfolio featuring well-known household brands such as Yoplait, Pillsbury, Old El Passo, and Blue Buffalo.

Engineering project overview

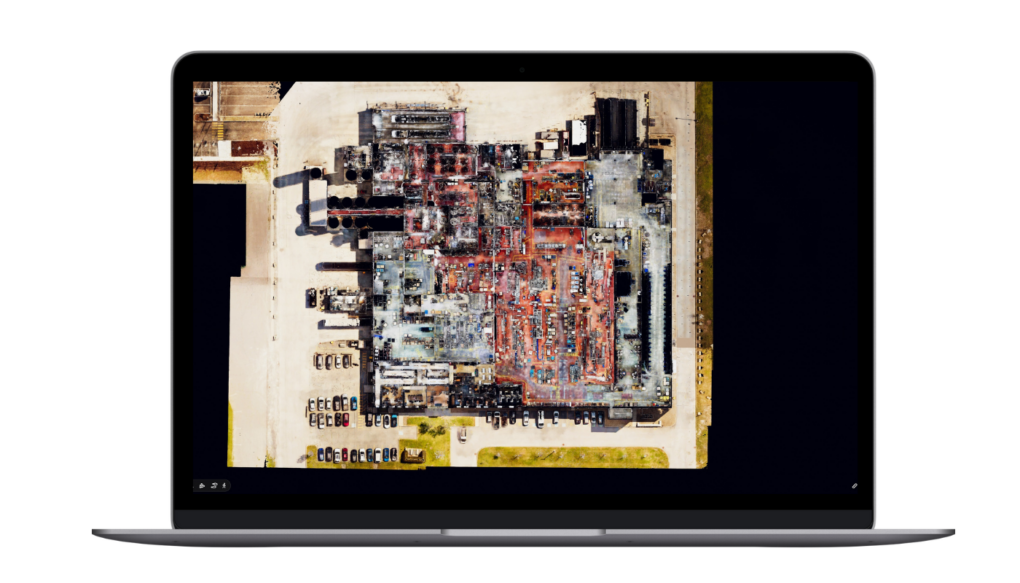

General Mills’ engineering team sought to create a 3D model of their St-Hyacinthe plant. As the existing 2D plans were outdated, they recognized the need to ensure new construction plans would be up to date with the as-built site, a process that often entails on-site measurements and validations. The department was also preparing for a roof reinforcement project and planned to utilize 3D scanning to capture the site and Prevu3D software as an integral engineering tool.

Based on their accuracy requirements, Prevu3D 3D scanning partners selected the NavVis VLX 3 as the device to capture the interior, exterior, roofs, and spaces in between.

The scanning data was processed in RealityPlatform to create a detailed mesh digital replica, providing a complete understanding of the site and facilitating engineering workflows.

Managing buildings, I must ensure that construction plans are up to date, often requiring on-site measurements and validations. This information is available in our 3D environment on the Prevu3D platform, which is accessible even when working from home or on-site with suppliers.

Yves Gaudreault

Mechanical Engineer, General Mills

Streamlining the design process

Prevu3D allowed General Mills to enhance the design stage of the roof reinforcement structure without traveling on-site, limiting safety risks and accelerating planning execution. Our solution helped the company accelerate the engineering project without spending several hours carrying out these measurements.

Yves Gaudreault, a mechanical engineer, has a crucial role in ensuring that buildings and services, with a specific focus on energy and the environment, are aligned with process changes. He emphasizes that his previous experience working with BIM models during the construction of a new factory has already convinced him of the significance and practicality of Prevu3D software for designing installations, whether it involves the initial design or modifications.

Implementing Prevu3D solutions

Integrating the Prevu3D software into the General Mills system was seamless and didn’t require specialized hardware. The solution runs on any standard computer and provides web and desktop applications. The team received initial training on basic navigation and ongoing support from the designated customer success team to maximize the engineering design workflows with RealityPlan.

Ongoing design engineering projects

The General Mills engineering team is currently in the final design stage of the roof reinforcement project, utilizing the Prevu3D solution. The work is scheduled to be carried out during the summer of 2024.

By enhancing the usability and accessibility of scanning data, Prevu3D maximizes the potential for value creation in 3D workflows, benefiting a broader range of end-users.

About Prevu3D digital twin software

Prevu3D provides an end-to-end platform that empowers industries to harness the full potential of 3D technology. Our asset-based software solution connects real-world assets, data and people to manage industrial installations efficiently, reduces risks and delays in engineering projects, accurately documents factory infrastructure, and enhances stakeholder communication.

RealityPlatform™

Host, process and manage reality capture data all on RealityPlatform™. Convert point clouds to textured meshes for easy accessibility and richer visual context. Collaborate with stakeholders through detailed 3D environments.

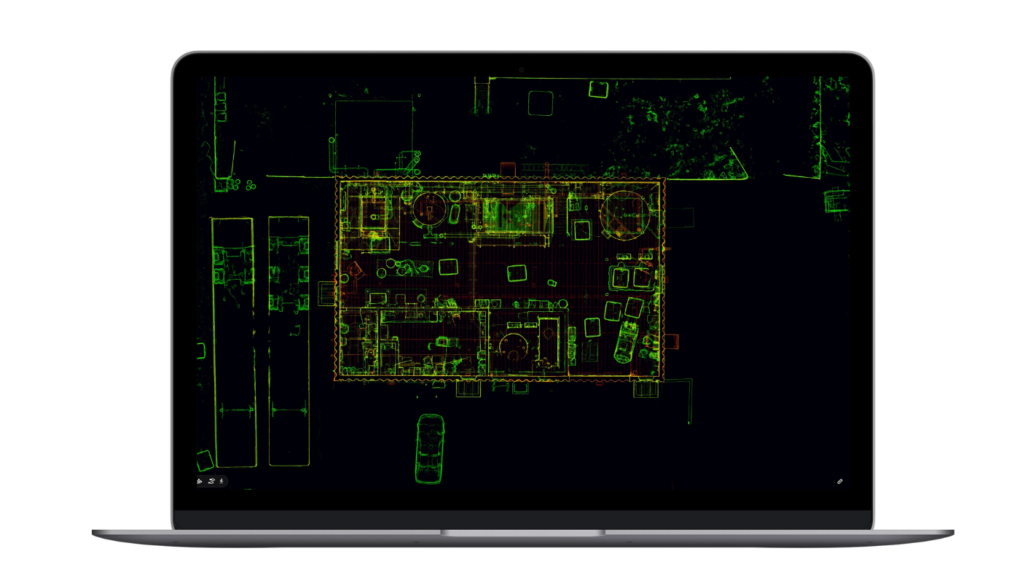

RealityPlan™

Accelerate your engineering design process with asset definition tools. Easily cut meshes to create RealityAssets and combine CAD metadata to classify, organize, and search assets in a single source of truth. Seamlessly integrate CAD and BIM models to create, save and share new projects with stakeholders to expedite decision-making.

Join industry-leading manufacturers benefiting from Prevu3D software solutions.