Blog - September 9, 2025

Virtual Engineering Walkdowns for Early Design Teams

Challenges

Costly travel for site visits

Safety risks in hazardous environments

Incomplete data, repeat visits

Slow early design progress

Benefits with Prevu3D

Lower costs and risks

Instant, comprehensive site data

Accurate measurements

Faster, collaborative design

Rethinking the First Step in Project Design

In the early phases of engineering projects — Pre-FEED (Front-End Engineering Design) and FEED — site walkdowns are essential. Engineers travel to facilities to assess conditions, take measurements, capture photos and videos, and verify existing layouts.

But traditional walkdowns come with high costs and risks. Travel expenses add up quickly, especially for remote or international sites and the risk to personnel safety increases as multiple engineers enter hazardous operating environments. And despite all the effort, teams often return with incomplete data, requiring repeat visits that further increase project costs and delay design progress.

For design teams tasked with producing accurate early estimates and layout options, this process was inefficient and limited their ability to move quickly.

The Prevu3D Approach

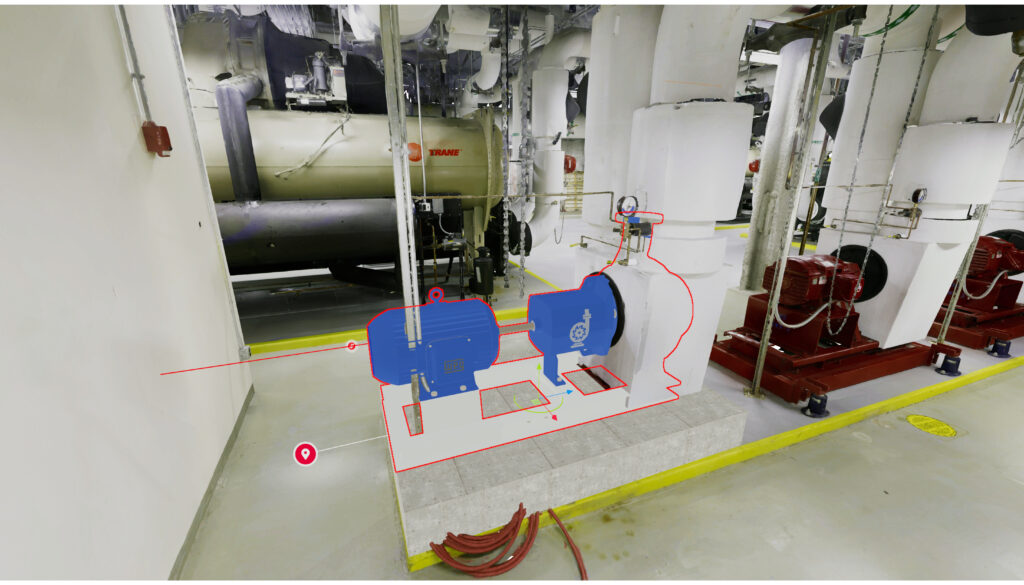

Instead of sending teams into the field, the organization leveraged Prevu3D to bring the field to the engineers. Using a combination of ground-based and drone scans, they created a high-fidelity 3D mesh of the facility.

This mesh became the foundation for virtual walkdowns. Engineers could remotely explore the facility from their desktops, measure distances, verify tie-in points, and share comments directly within the model with other stakeholders. Prevu3D’s seamless, browser-based environment ensured everyone — from mechanical engineers to supply chain specialists — could participate without installing specialized software.

By digitizing the walkdown, design teams gained the same visual and dimensional insights they would from being on-site, but without the associated costs and risks.

The Results

The shift to virtual walkdowns delivered immediate benefits:

- Reduced travel costs and safety risks. Engineers no longer needed to travel for routine site assessments.

- Faster access to site data. Scans provided instant visibility, enabling quicker decision-making in early design phases.

- Improved collaboration. Teams could conduct virtual reviews together, sharing observations and comments in one centralized platform.

- Fewer repeat visits. High-fidelity scans ensured comprehensive coverage, reducing the likelihood of missed details.

- Precision measurements. The design teams now had access to precision measurement tools that helped them make better decisions, faster.

By replacing physical walkdowns with digital equivalents, design teams were able to spend more time engineering solutions and less time traveling, measuring, and documenting.

Why It Matters

In an industry where early decisions shape multimillion-dollar projects, reliable and accessible site data is critical. Prevu3D’s virtual walkdowns ensure design teams have all the information they need, without the inefficiencies of traditional site visits.

This isn’t just about cost avoidance — it’s about enabling a new level of agility. Teams can start design work immediately, iterate faster, and engage more stakeholders in the process. For EPC organizations, virtual walkdowns represent a step change in how projects are initiated and executed, setting a stronger foundation for success.

Book a demo with Prevu3D and see how engineering leaders cut design cycles, eliminate costly site visits, and prevent million-dollar errors before they happen.